Documents and Resources:

| About The Product

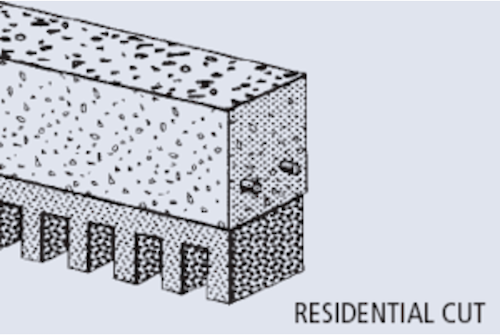

Frost Cushion Description

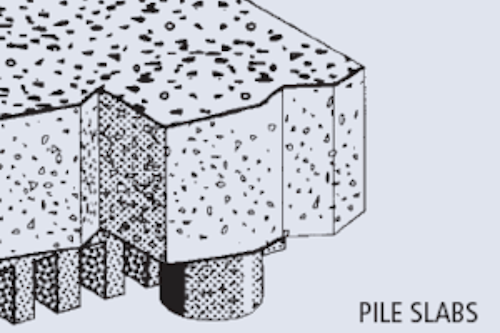

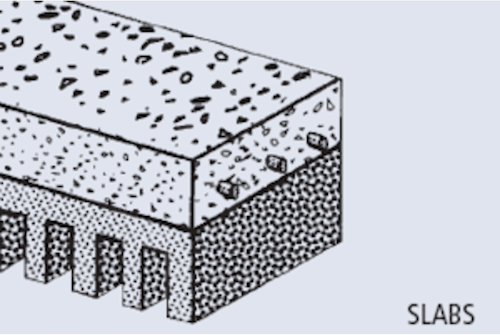

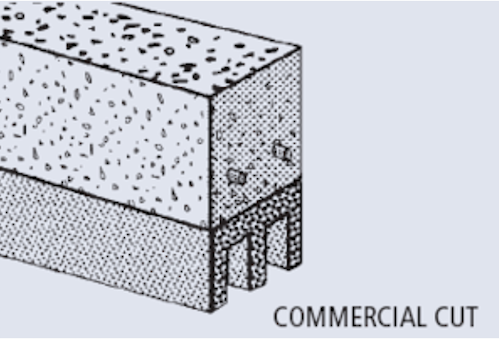

Frost Cushion is manufactured from inert closed cell expanded polystyrene (EPS). It is used under concrete grade beams forming voids to compensate for frost and moisture-induced swelling of underlying soils that might otherwise lift or fracture the concrete structure. Frost Cushion will not collapse due to water absorption. It resists soil movement into the void space. Frost Cushion has excellent resistance to freeze/thaw and has low moisture absorption properties. It is not biodegradable and has no pest nutrient value.

Applications

Frost Cushion can be used under grade beams and other structural concrete members. It will support a total working load equivalent to the weight of 4 feet (1200 mm) of concrete. AMC is registered by the International Standards Organization (ISO) under the ISO 9001 Quality Assurance Program. This is a set of standards and criteria which is internationally recognized as an assurance of product quality and consistency.

Industry Acceptance

Since 1951, EPS has been one of the most widely used thermal insulations in the world and is applied increasingly in architecturally designed energy-efficient buildings. Its low cost, versatility, and high R-value per dollar make EPS insulation the preferred product of architects, specifiers and application contractors across the country. It is recyclable, has no CFC’s or HCFC’S.

Construction today and in the future is, and will be, characterized substantially by the requirement for energy savings, noise insulation, environmental protection, LEED certification, etc.

Virtually all industrialized countries today have statutory minimum requirements for the structural thermal insulation of heated and air-conditioned buildings. Now, even in countries with moderate to tropical climates, a comparatively high level of construction thermal insulation is prescribed, as in the case in countries with relatively low winter temperatures. This is due to the fact that in these countries summer thermal insulation – namely the energy lost in the air-conditioning of a building on hot summer days is greater than that in the heating of buildings with cold out-side temperatures in winter.

Types and Sizes

Styrobar® 16 and Styrobar® 22 are available in all standard sizes starting at 1/2″ thick to 12″ thick, in 2’x4′, 2’x8′, or 4’x8′ sheets. Custom thickness up to 26″ are available on a special order basis. Styrobar® is available with either a butt edge or shiplap edge. It can also be ordered with recessed cut-outs on 16″ or 24″ centers for 1″x3″, 1″x4″, or 2″x4″ dimensional lumber. All products are poly wrapped for ease of handling.

Availability

STYROBAR® insulation is manufactured by AMC Foam Technologies Inc. in Winnipeg, Manitoba. It is readily available for prompt delivery by the bundle or full truckload lot. Manitoba, Saskatchewan, Northwest Ontario, and the upper mid-USA States are easily accessed from our Winnipeg manufacturing facility. Contact AMC Foam Technologies Inc. for a list of local distributors.

Are you ready to start chatting? Contact us today.