| About The Product

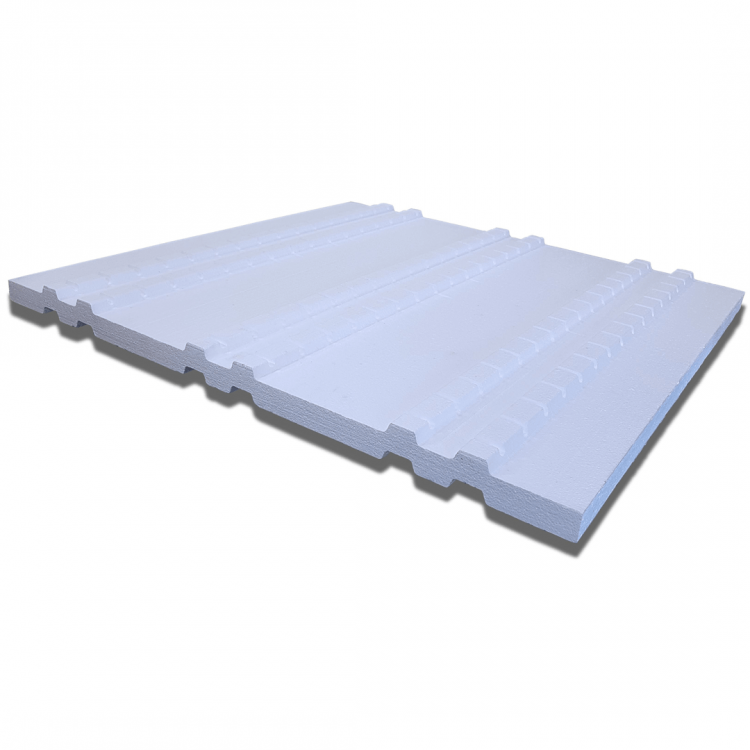

Hydronic Heating Insulation

Insulworks is a unique insulation panel designed especially for hydronic heating applications. Its primary functions are to conserve energy and reduce cost and labour. Insulworks provides an efficient thermal barrier between the heated slab and the underlying ground. Also, in preventing the ground from becoming a linked “thermal flywheel” to the slab, Insulworks permits fast and accurate room temperature response to temperature controllers. The use of Insulworks may also reduce the size and cost of system hardware.

Using Insulworks will reduce project costs and speed installation because the usual method for positioning tube by tying it down to wire mesh has been replaced. The tube is simply “stepped” into the Insulworks panels, saving a great deal of backbreaking labour. The cost to purchase and install wire mesh may also be eliminated. Insulworks is manufactured in a 4′ x 4′ (1220 mm2) panel in several thickness’s for 13 mm (1/2″) and 15.8 mm (5/8″) tubing and 19 mm (3/4″) I.D. tubing, and R- Values ranging from R-6 to R-12, and over. Insulworks is produced from Type 2 expanded polystyrene (EPS), a high density, closed cell foam insulation. It is appropriate for use on and underground, and concrete structures.

It will never rot, support mold or mildew, and has no pest nutrient value. Since EPS contains ordinary air, insulation values will not break down due to the escape of CFC or HCFC insulating blowing agents. EPS is relatively permeable, and will breathe moisture vapor. At a minimum compressive strength of 16 psi (110kPa.), Insulworks will support the weight of 16 vertical feet (4.8 meters) of concrete, or equivalent.

Applications

Insulworks can be used under slab-on-grade, in sandwich slab application, snow melt systems and other applications under concrete where radiant panel heating is required. Insulworks has been designed to support the weight of cast-in-place concrete, construction activity and working loads, machinery and heavy vehicle loading where the concrete slab has been designed for such purposes.

Specifications and Compliances

AMC is registered by the International Standards Organization under the ISO 9001:2008 registered company Quality System Standard, a set of standards and criteria that is internationally recognized as an assurance of product quality and consistency. Insulworks is manufactured to meet the intent of ASTM C578-01 Type 2 and CAN/ULC S701-97 Type 2. AMC’s products are certified under the Warnock Hersey Third Party Certification Program.

Are you ready to start chatting? Contact us today.